May 9 2023

EVs continue to change the landscape of the auto industry at a rapid pace and many questions arise for consumers and businesses alike. In our previous EV article, we covered the topic of EV charging and charging infrastructure, one of the biggest factors in the adoption of EVs. As a follow-up, we thought it would be helpful to address some of the key components of an EV, as well as some of the ways in which they differ from their internal combustion engine (ICE) counterparts.

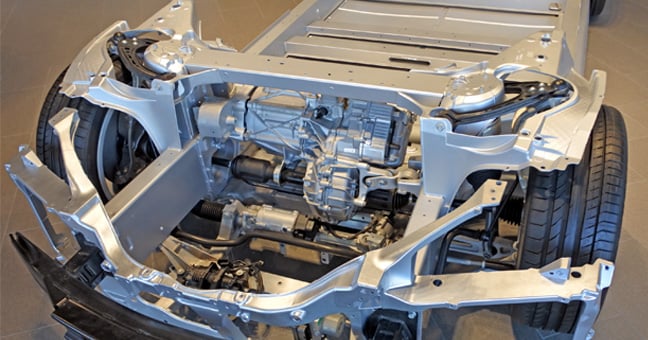

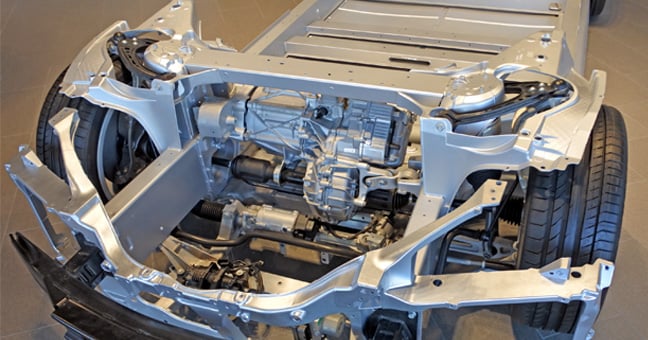

While EVs have far fewer moving parts than a traditional ICE vehicle, there’s a steep learning curve as many of their key components are quite different - here’s a rundown of the most important parts:

The battery pack, consisting of lithium-ion batteries, is the most important and expensive component of an EV, storing energy and giving power to the entire vehicle including the electric motor that allows the vehicle to move. While these batteries have come a long way, according to the U.S. Department of Energy, “research and development are ongoing to reduce their relatively high cost, extend their useful life, and address safety concerns in regard to overheating.” You can learn more details about EV batteries in this CarandDriver article.

Though battery packs are exclusive to EV vehicles, ICE vehicles do have a much smaller battery present that both powers the starter, as well as some of the electronic components while the vehicle is off. The alternator takes over once the ICE vehicle is running.

EVs use an electric motor (or two, depending on EV model or drive type), to drive the wheels, similar to the engine of an ICE vehicle. Electrical energy is transferred from the battery to the motor(s) and is then converted to mechanical energy. The number of motors and their placement determines whether the EV is front-wheel, rear-wheel, or all-wheel drive. Electric motors are far less complex than internal combustion engines and do not require maintenance, contrary to the latter.

The power electronics in an EV are composed of inverters, converters, controllers, and the onboard charger. These components contribute to the flow of electricity throughout the vehicle, primarily from the battery to the electric motor, as well as other powered components of the vehicle, such as the heating and ventilation system, lighting, infotainment, etc.

More specifically, power electronics are responsible for converting direct current to alternating current (DC to AC inverter) or the inverse (AC to DC converting), as well as DC/DC converters which either increase battery voltage (boost) or decrease battery voltage (buck).

The charging system is made up of the charging port where the cable is plugged in, the charging cable, and the onboard charger that converts AC power from the electrical grid into DC energy which is then sent to and stored in the battery. DC fast charging means AC power is converted to DC outside of the vehicle and sent directly to the EV battery, bypassing the onboard charger. Learn more about EV charging in our previous article of the series.

The thermal management system, comprising radiators, fans, and coolant pumps, is a crucial component of EVs. This system helps regulate the temperature of the battery pack, electric motor, and power electronics to ensure they are operating at an optimal temperature for the best performance as well as increasing longevity. Without a thermal management system, these components would be susceptible to damage through overheating or excessive cooler conditions. Not only does the regulation of temperature protect the vehicle's most valuable parts, but it also helps maximize efficiency and range by minimizing energy loss. While ICE vehicles may not be as greatly impacted by extreme weather conditions, performance, and fuel efficiency can still be reduced.

You may already be familiar with regenerative braking as one of the key functionalities of a hybrid vehicle. This system converts the kinetic energy generated during braking into electrical energy that is stored in the battery, which in turn reduces the amount of energy required from the battery.

Unlike traditional ICE vehicles, the regenerative braking systems store energy back into the battery that would otherwise have been lost. These systems also help reduce wear on the brakes by leveraging the electric motor to slow down the vehicle when activated, such as driving down a hill or approaching a stop sign.

The vehicle control unit (VCU) is responsible for controlling and coordinating processes relating to the functional aspects of an EV. In other words, it acts as the brain of the vehicle. The VCU receives information (such as battery temperature, motor speed, vehicle speed, etc.) from various sensors and systems, and ensures that the vehicle operates efficiently and safely. Additionally, the VCU communicates with other control units including the battery management system (BMS) and motor controller to ensure all systems are working together.

Understanding the core components of an EV and how they work together is essential in enabling EV owners to help extend the life of these vehicles and ensure they are functioning optimally. Automotive businesses also benefit from a comprehensive knowledge of EV structure to better protect their investments and develop the best possible business processes for managing their EV-related workflows.