Dec 4 2014

Aluminum dominates as the choice material for wheels and engine blocks in the automotive industry. In the last few decades, the use of aluminum auto technology has increased. Beyond its lighter weight which can enhance fuel efficiency and performance capabilities, aluminum is recyclable and can improve safety by absorbing more crash energy than steel. However, it is not without disadvantages.

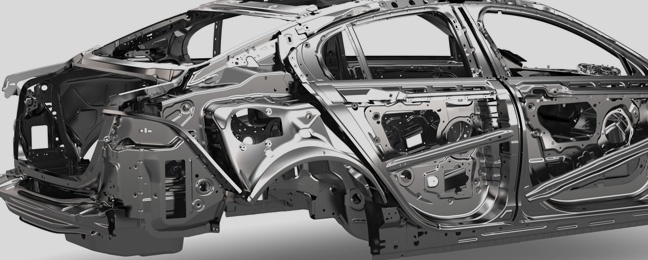

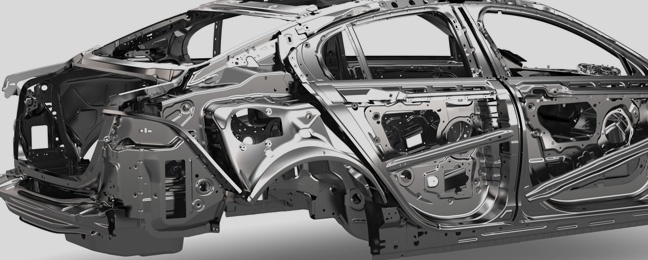

Though the first aluminum car (aluminum panels on a wood frame) on the market dates back to 1913, until recently aluminum never seemed to gain traction as a major structural component, ie. frames and panels. While small-batch vehicles such as the Rolls-Royce Phantom feature an aluminum frame, it's production vehicles such as Ford's F-150 as well as the Audi A8 and BMW i8 that offer the next generation of aluminum auto technology.

Ford's new full-sized pickup trucks weigh in 700 pounds lighter than their previous F-Series models. By switching from heavy steel panels to high-strength, yet lightweight aluminum panels, Ford is able to produce a lighter and more fuel efficient truck. The new F-150 is the first high-volume vehicle to feature an all-aluminum body.

According to the Aluminum Association,

"When applied to an optimized automotive body structure, aluminum can provide a weight savings of up to 50 percent compared with traditional mild steel structure."

A lighter weight vehicle can offer improved:

An aluminum body frame can absorb a higher energy crash impact versus mild steel. Because of its lighter weight, the automotive industry could increase the thickness of body panels without adding extra weight to the vehicle. According to a survey of North American automakers, these advantages are the reason they're projecting the aluminum content of the average vehicle to nearly double by 2025.

When a vehicle's weight is reduced and fuel economy improved the latter directly benefits the environment with emissions reduction. The Aluminum Association states "compared with a fleet of traditional steel vehicles, aluminum use saves the equivalent of 108 million barrels of crude oil in energy."

Aluminum also offers a high-rate of recyclability. Almost 90 percent of automotive aluminum scrap materials are recycled annually. A single ton of recycled aluminum scrap creates an energy-savings equivalent of approximately 2,300 gallons of gasoline.

While aluminum can be recycled to benefit the environment, the actual refinery process for the production of aluminum has a waste product called red mud. The E.P.A. reports that red mud is "caustic and no secondary use has been made of the waste from the tailings impoundments." Elevated levels of both arsenic and chromium have been found in the red mud.

Aluminum does not come without its disadvantages. On average, aluminum is more expensive than steel, as much as two to three times more. However, expense alone is not the only disadvantage aluminum may have when compared with steel frames and body panels.

A key disadvantage is aluminum's inability to be welded easily. If a steel door panel or frame suffers a crack, often it can be welded back together easily, primed and repainted so it's difficult to tell any body work has been performed. This can't be done with aluminum. Steel also can be bent and shaped as needed.

Body shops and even dealer service centers currently are equipped for steel work with technicians skilled in the art of welding and steel fabrication. The cost for switching over to an infrastructure designed specifically for all-aluminum vehicles or mass production of aluminum vehicles and components would be high.

Aluminum does have specific advantages including its capability for safer, higher performance and environmentally friendly automotive technology. However, the expense of aluminum, the lack of automotive aluminum manufacturing infrastructure and the fact that aluminum can't be welded or easily bent like steel are distinct drawbacks.

Will aluminum become the new steel within the automotive industry?

According to the Wall Street Journal, GM plans to use a mix of different materials including carbon fiber, aluminum, and steel to meet weight requirements in the future, rather than refitting all the manufacturing plants for just aluminum. Toyota plans to encorporate an aluminum hood into the 2018 Camry.

Though many OEMs have plans to increase the use of aluminum, it's tough to tell if it will become the primary body and frame material, or when this would happen given the current obstacles. It will take time and further studies before a definitive answer can be declared.

Please share your thoughts about the future of aluminum in the auto industry in the comments section below!

Proceed to the next article on Car Infotainment Systems